Discover

the new XBC!

Any Questions?

What do I have to consider for autonomous driving in braking systems?

Redundant communication has to be built into the network architecture. A redundant power supply incorporates, for example, one battery configured to power at least one vehicle subsystem and a second to power an electric motor to propel a vehicle. The availability of degradation strategies is important in order to sustain safe automated driving until the driver accepts a request to take over if a hardware failure occurs. The iDBC² brake system acts as a smart actuator in interaction with the vehicle chassis control domain or ADAS ECU.

How can I reach SAE autonomous driving level 3 and higher?

This level can be reached via redundancies of functions and architecture. Redundant functionality is one key aspect required from level 3 and up. This applies to base brakes, ABS, EBD (electric brake force distribution), EPB (electronic parking brake), and AEB (automatic emergency braking).

Will I be disturbed by brake system noise in my electric vehicle?

There is no ABS noise audible to the driver as result of the positioning of the ABS/ESP control unit remotely to the noise-sensitive firewall. Key X-Boost functions such as regeneration blending and AEB (automatic emergency braking) are also not audible to the driver.

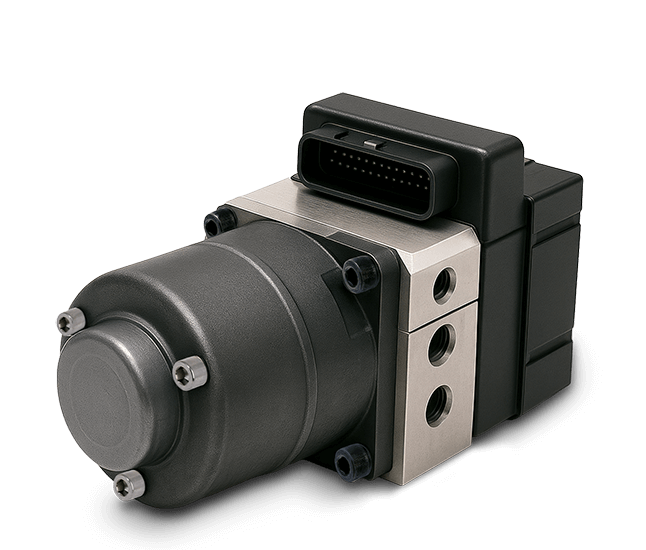

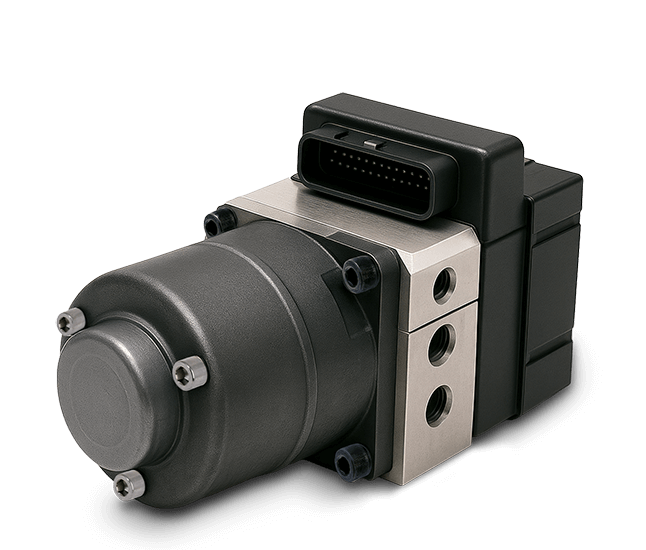

How do I optimize the crash zone in my vehicle?

XBC supports new vehicle concepts with different interior concepts and dimensions. The system dimensions are a huge integrational advantage - ideal for crash zone optimization and the design of shorter-length, new vehicles. This is enabled by having two smaller components, of which one, that is place in front of the driver, is short and the other can be freely positioned within the motor compartment.

How can I use a modern braking system in small vehicles?

The 2-box configuration of the XBC brake system means that there is valuable space for e.g. E/E components in the most suitable area (typical location of a 12/48V battery). The flexibility in positioning the units allow smart use of tight space in the motor compartment of e.g. small vehicles.

Can I use one brake system for left and right-hand drive vehicles?

The compact design of the XBC with remote pedal unit interface, allows the use of the system in left- and right-hand drive vehicles with very similar good use of the space in the vicinity of the brake system in both scenarios.

How do I ensure that the pedal feeling does not change with or without regeneration?

Consistent pedal feeling is ensured first by hydraulic decoupling of the brake pedal from the brake circuits in active mode. The actual brake pedal feedback/feeling results from the pedal feel emulator and the use of smart algorithm, allowing customization of the pedal response.

Is regenerative braking with an electric powertrain supported?

Yes, XBC is designed to enable regenerative braking using electric motors on one or even more axles.

What are the limits of regenerative braking?

Regenerative braking up to max. deceleration (1g or more) is possible due to an upgraded safety concept and smart use of ADAS sensors.

Do I still get feedback from the brake pedal while using ABS?

Yes, you still get the same feedback from the brake pedal while using ABS.

Does the brake pedal feel different to what I’m used to?

For the driver, the brake pedal feeling is the same as usual and stays the same regardless of the reduced application of the friction brakes during energy recuperation that may occur during deceleration. This is due to hydraulic decoupling of the brake pedal from the actual pressure generation.

Is the system compatible with my existing brake architecture?

Yes, a vacuum booster can be easily exchanged for an XBC system.

Can I use my existing ESC unit?

Yes. The functional scope depends on the project requirements.

Can I use the system in different vehicle architectures (FWD, RWD, AWD)?

Yes, the booster and the regenerative braking strategy are compatible with all vehicle architectures, for any kind of vehicle and application.

Is my XBC system ready for the future?

Yes, functional updates can enable ADAS, Level 3 and higher compatibility (no HW changes are required).

How can I reduce C02 emission?

CO2 emission is reduced through the implementation of Zero drag brake calipers control, which improves vehicle handling, efficiency, and component life. In addition, the Power-on-Demand system minimizes the average power consumption.

How can I achieve the shortest possible braking distance?

The system is already optimized for world class braking distance under controlled braking (ABS) with deceleration >1 g.

How can I improve the system reaction time?

Through the use of the proprietary Piston Pressure Control (PPC), that has been optimized since invention of IBS technology in 2005. An automatic emergency brake (AEB) functionality with a minimum TTL (Time-to-Lock) is already integrated.

Can my braking system increase the autonomy (range)?

Yes, through innovative strategies that have been developed in electric racing series (Formula E, WEC) to maximize regeneration during braking. Smart anticipating brake caliper prefill is a feature of the system.

Can I change my brake setup during operation?

Adjustable system response during operation is possible via software.

Can I have control of brake functionality from vehicle level?

Yes, the system offers open platform interfaces. For example, individual torque control (TV) or regenerative brake control. Over the air capability allows for downloading applications, services and configurations over a mobile or cellular network.

Does the system fit into my domain architecture?

Functional integration of the electric powertrain and braking system is possible. Functionalities have been designed for distributed, zonal and central architectures.

Does the brake system support vehicle motion control?

The brake system can be used as smart actuator. Future functions include BtS (Brake-to-Steer) and BtTV (Brake-to-Torque-Vectoring).

Contact us

We Look Forward To

Your Enquiry

We are at your disposal for enquiries of any kind.